Day and night, till march 31st, the winegrowers who are also distillers, live according to the tempo of theirs stills and the process called « double chauffe » or « repasse » in french i.e, two separate heatings, in a special « charentais » copper still. The distillation is a particular moment which appeals to emotional senses of sight and smell : a sweety temperature near the stills, the slow flow of the eau-de-vie, and the subtle scents diffusing in the air.

Since the beginning of cognac story, the distillation is still the same with this special double process of heating.

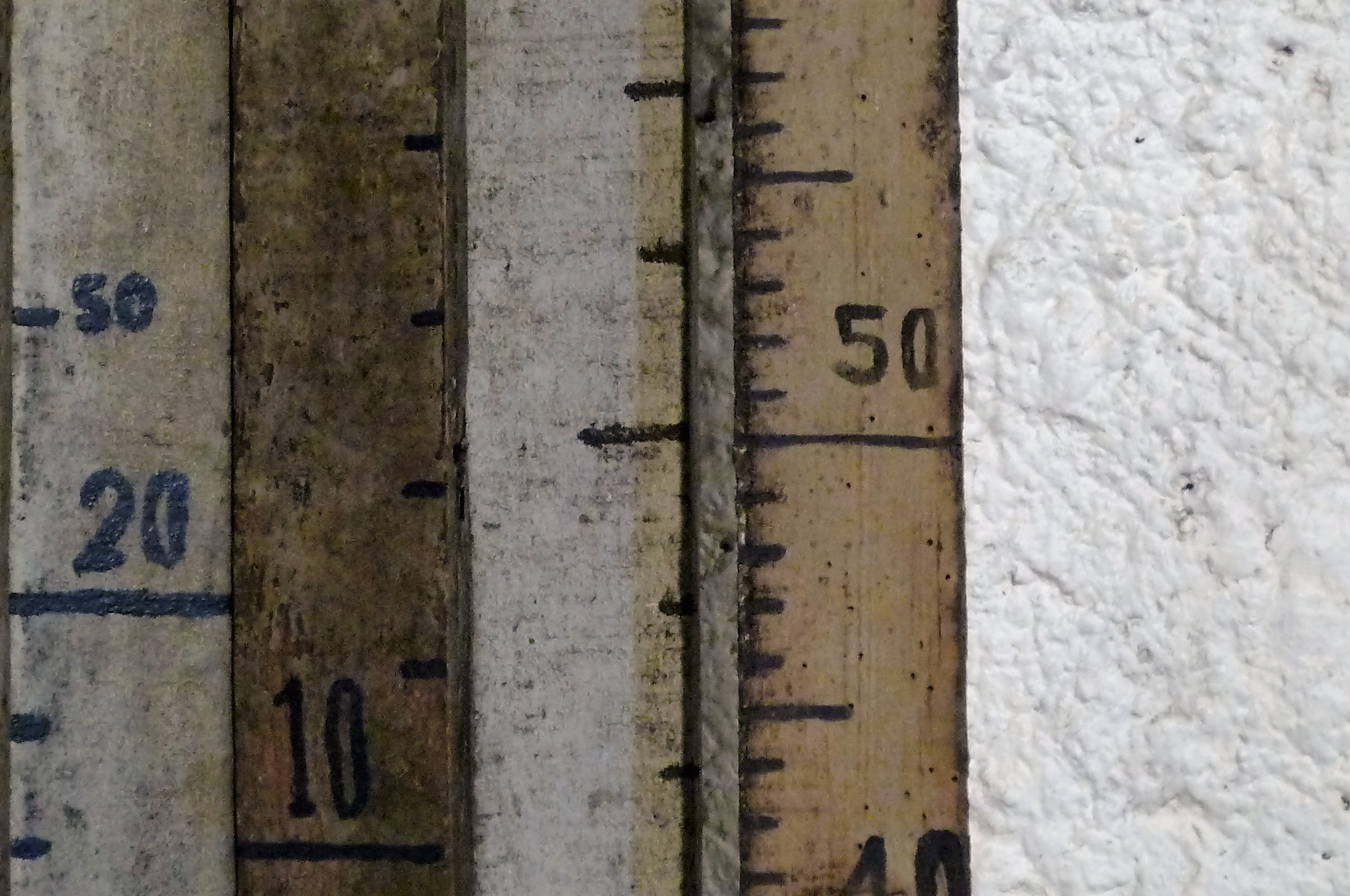

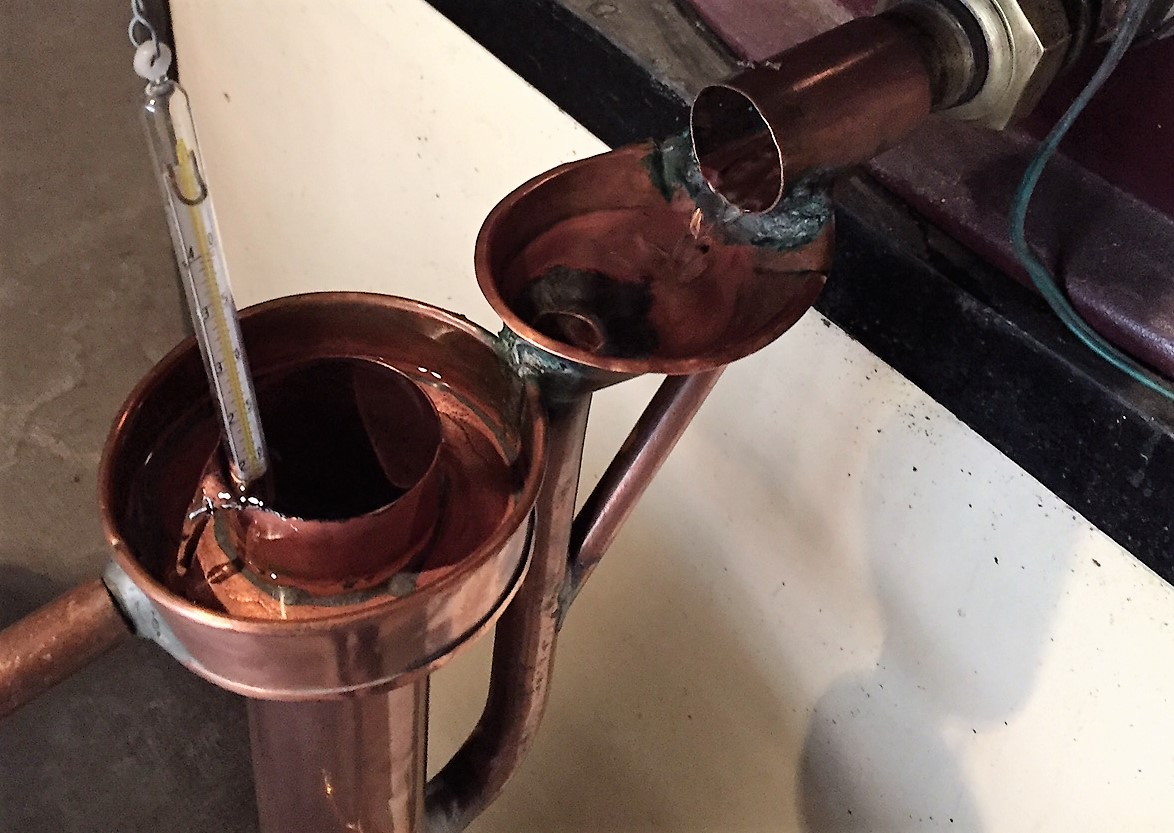

At the time of distillation, wines must have an alcoholic degree between 7% and 12%. First, the white wine is poured in the boiler and brought to its boiling point. Alcohol vapors are freed and collected in the still-head, then they cross the swan-neck to arrive into the coil. Upon contact with the coolant, they condense, to become the “brouillis”(between 28 and 32 % of alcohol content).

Thanks to Line Sauvant from Cognac Guillon Pinturaud who opened the door of her distillery for us. Next post on her, and the family dynasty.

Thanks to Line Sauvant from Cognac Guillon Pinturaud who opened the door of her distillery for us. Next post on her, and the family dynasty.

The brouillis starts to flow, we call it « la mise au courant ». About 12 hours are necessary for the first distillation. Then the « brouillis » goes back again to the boiler for the second distillation known as the « bonne chauffe ». About 8/10 hours later the most delicate moment happens : the cutting « la coupe », needs all the attention and skill of the distiller. After the « heads » (1 or 2 % of the volume) comes the « heart », as its name suggests, this so bright and clear color liquid will be future cognac. The cutting takes place just at the crush moment when « seconds cuts » are going to appear. Again 12 hours are necessary for the second distillation.

Depending from methods, the heads, seconds cuts and tails may be redistilled with next distillation of wine or brouillis, totally or just some parts. A secret of fabrication for each distiller… The heart is directly poured in oak barrel, an other story begins, the ageing process.

Lost along the way ? Don’t worry, this small video will explain you all the process, thanks to BNIC

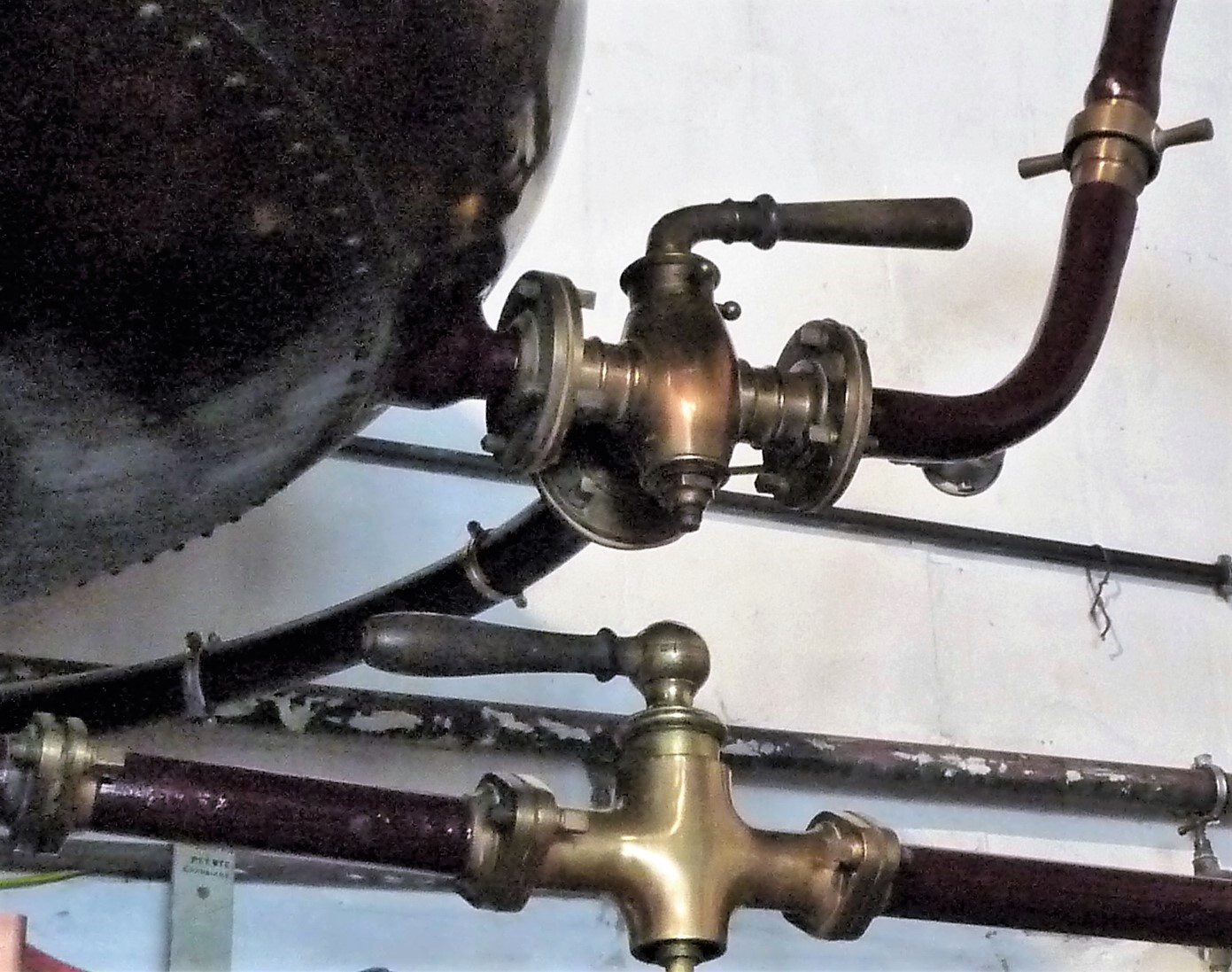

The process is quite stunning, but what about the tools, theses stills, some of them century old, still-head with different shapes,onion, turban, olive, prolonged by a swan-neck, shiny coppers, red bricks, dark carpentries, a magic atmosphere…

Even the modern ones, computer controlled, have been produced with the same attention to the details.

But nevertheless, no computer can replace the skill, the eye and the smell of the distiller particularly in very important moments. It will be our next post on the blog.